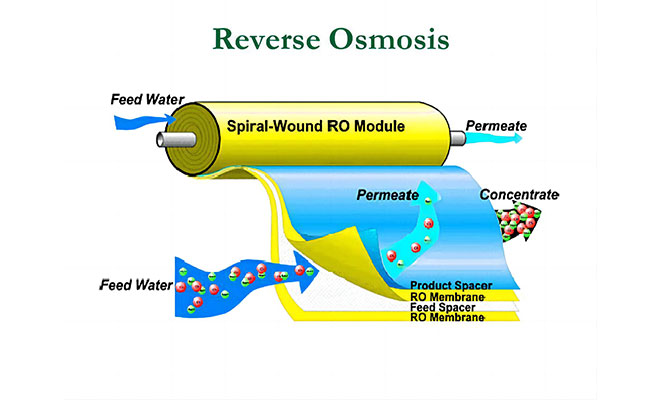

Separate the pure water from the solution containing solute with a semi permeable membrane that can only pass through water. At this time, the water on the pure water side will spontaneously pass through the semi permeable membrane and enter the solution side. The water surface on the solution side will rise. This phenomenon is penetration. When the liquid level rises to a certain height, the pressure on both sides of the membrane reaches equilibrium, and the liquid level on the solution side no longer rises. At this time, there is a pressure difference on both sides of the membrane, which is called osmotic pressure. If a pressure greater than the osmotic pressure is applied to the solution side, the water molecules in the solution will be squeezed to the pure water side. This process is just the opposite of osmosis, which is called reverse osmosis (RO). We can see from the process of reverse osmosis that due to the pressure, the water molecules in the solution enter the pure water, the amount of pure water increases, and the solution itself is concentrated.

Item | Reference value |

Comprehensive desalination rate | >97~99% |

Intercepted molecular weight of organic matter | >150MW |

Bacterial elimination rate | >99% |

Pyrogen elimination rate | >99% |

Silica removal rate | >98.5% |

Removal rate of heavy metal ions | >96~99% |

Item Type | Water output (m3/h) | Minimum water intake (m3/h) | Desalination rate (%) | Temperature of the working water (℃) |

FSJ41X-0.5XB | 0.5 | 2 | 98 | 5-35 |

FSJ42X-1XB | 1 | 2.5 | 98 | 5-35 |

FSJ42R-2XB | 2 | 3.6 | 97 | 5-35 |

FSJ43R -3XB | 3 | 5.0 | 97 | 5-35 |

FSJ43R-4XB | 4 | 5.3 | 97 | 5-35 |

FSJ82R-6XB | 6 | 1.1 | 97 | 5-35 |

FSJ82R-8XB | 8 | 13 | 97 | 5-35 |

FSJ83R-10XB | 10 | 15 | 97 | 5-35 |

FSJ83R-15GB | 15 | 20 | 97 | 5-35 |

FSJ84R-20GB | 20 | 26 | 97 | 5-35 |

FSJ85R-25GB | 25 | 35 | 97 | 5-35 |

FSJ86R-30G | 30 | 40 | 97 | 5-35 |

FSJ86R-50G | 50 | 67 | 97 | 5-35 |

Item Type | Water output (m3/h) | Minimum water intake (m3/h) | Desalination rate (%) | Temperature of the working water (℃) |

FSJ41X-0.5XB-2 | 0.5 | 2.2 | 98 | 5-35 |

FSJ42X-1XB-2 | 1 | 2.8 | 98 | 5-35 |

FSJ42R-2XB-2 | 2 | 4.1 | 97 | 5-35 |

FSJ43R -3XB-2 | 3 | 6.5 | 97 | 5-35 |

FSJ43R-4XB-2 | 4 | 7.8 | 97 | 5-35 |

FSJ82R-6XB-2 | 6 | 12.5 | 97 | 5-35 |

FSJ82R-8XB-2 | 8 | 15 | 97 | 5-35 |

FSJ83R-10XB-2 | 10 | 15 | 97 | 5-35 |

FSJ83R-15GB-2 | 15 | 31 | 97 | 5-35 |

FSJ84R-20GB-2 | 20 | 38 | 97 | 5-35 |

FSJ85R-25GB-2 | 25 | 41.25 | 97 | 5-35 |

FSJ86R-30G-2 | 30 | 47.5 | 97 | 5-35 |

FSJ86R-50G-2 | 50 | 79.5 | 97 | 5-35 |

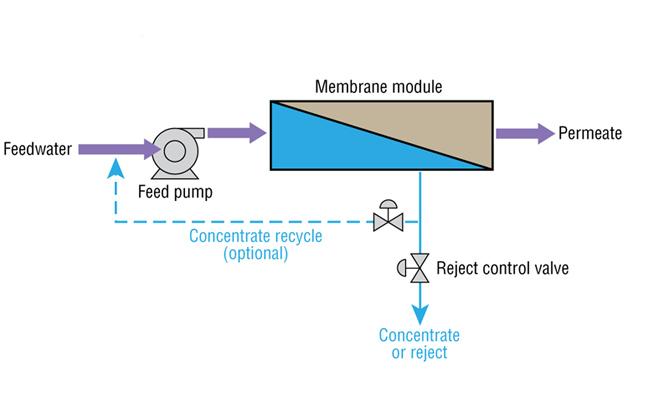

The reverse osmosis membrane used by the reverse osmosis equipment is a semi permeable spiral roll membrane. When the raw water is sent to the reverse osmosis membrane at a certain pressure, the water passes through the micro aperture on the membrane and is collected to obtain pure water. The impurities in the water, such as soluble solids, organic substances, colloidal substances and bacteria, are intercepted by the reverse osmosis membrane, concentrated in the intercepted solution and removed. Single stage reverse osmosis can remove more than 97% of the dissolved solids in the raw water, and double stage reverse osmosis can remove more than 99% of the dissolved solids, more than 99% of the organic matter and colloid, and almost 100% of the bacteria. The two-stage reverse osmosis equipment uses the first stage pure water to enter the second stage as raw water, which can make the pure water produced reach higher quality. It is suitable for the needs of high-purity water production, and can also be used in situations where the raw water conductivity is high.

At present, reverse osmosis equipment is one of the most advanced water treatment equipment in the world. With low operating cost, economy, convenient operation and reliable operation, it is the first choice for businesses to produce pure water. The production capacity of the equipment is the value under 25 ℃ raw water and standard production conditions. Changes in water temperature and production conditions will affect the production capacity of the equipment.

Primary reverse osmosis unit

1. Applicable to areas with low salt content of raw water

2. Low total carbon (organic matter) of product water

3. Pollution free emission

4. Simple structure

Secondary reverse osmosis unit

1. Applicable to areas with high salt content of raw water

2. The outlet water conductivity is good

3. Low one-time investment

4. Low operation cost

5. Good stability

Phone:

E-mail:

Address:

Room 1904, Building 10, No. 218, Jiqingmen Street, Jianye District, Nanjing, Jiangsu, China