EDI plant water treatment module is usually placed behind the reverse osmosis system, which not only overcomes the lack of deep desalination of reverse osmosis effluent, but also further removes trace carbon dioxide, residual salt, silicon dioxide, boron and total organic carbon plasma in RO water, greatly improving the quality of purified water.

EDI plant water treatment is widely used in biotechnology, pharmacy and other industries that must generally comply with and comply with USP, EP, JP and ChP regulations.

※ Post EDI Ultrafiltration

※ A post EDI UF System with 6000 Daltons Molecular Weight Cutoff membranes serves to produce highly purified water having a compliance with low endotoxin values.

※ A post EDI UF can have a TOC reduction UV with 194 nm wavelength or 254 nm wavelength for bacterial control as an option.

Water inflow requirements | |

TEA(with CO2) | <25mg/L as CaCO3 |

Hardness | <1mg/L as CaCO3 |

TOC | <0.5mg/L |

Temperature | 5-43℃ |

PH | 5-9 |

Silicon | <0.5mg/L |

Free Chlorine | <0.05mg/L |

Water inlet pressure | 30-100psi |

Fe, Mn, H2S | <0.01mg/L |

Rate of recovery | 90-95% |

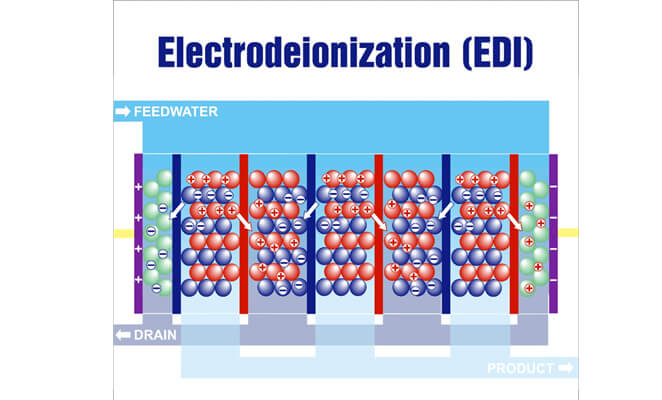

EDI stands for Electrodeionization, which is a water treatment technology that utilizes ion exchange membranes and an electric field to remove ions from water.

The EDI water treatment system is typically used to produce high-quality water for industrial and laboratory applications. The EDI plant water treatment system works by passing water through a series of ion exchange membranes and electrodes, which remove dissolved salts and other ions from the water.

Unlike other water treatment technologies, EDI water treatment does not require chemicals to regenerate the ion exchange resin, making it a more environmentally friendly option. EDI systems are also relatively compact and easy to maintain compared to other water treatment technologies.

Overall, EDI is an effective and efficient way to remove impurities from water, and it is commonly used in industries such as pharmaceuticals, electronics, and power generation.

Pharmaceutical Industry: EDI is extensively used in pharmaceutical manufacturing processes to produce water of high purity, which is essential for the preparation of medications, injections, and other pharmaceutical products. The consistent quality and reliability of EDI-treated water make it ideal for critical pharmaceutical applications.

Pharmaceutical Industry: EDI is extensively used in pharmaceutical manufacturing processes to produce water of high purity, which is essential for the preparation of medications, injections, and other pharmaceutical products. The consistent quality and reliability of EDI-treated water make it ideal for critical pharmaceutical applications.

Pharmaceutical Industry: EDI is extensively used in pharmaceutical manufacturing processes to produce water of high purity, which is essential for the preparation of medications, injections, and other pharmaceutical products. The consistent quality and reliability of EDI-treated water make it ideal for critical pharmaceutical applications.

Electronics Industry: In the electronics industry, EDI-treated water is used in the production of electronic components and devices. The high-purity water produced by EDI helps ensure the reliability and performance of electronic products by minimizing the risk of contamination during manufacturing processes.

Food and Beverage Industry: EDI is employed in the food and beverage industry for producing purified water used in beverage production, ingredient mixing, and other food processing applications. The consistent quality and purity of EDI-treated water contribute to the safety and quality of food and beverage products.

Biotechnology and Pharmaceutical Research: EDI technology is also utilized in research laboratories and biotechnology facilities for producing high-quality water used in various experiments, analytical procedures, and laboratory applications. The reliable and consistent performance of EDI systems is particularly valuable in research environments where precise water quality is essential.

| DOCUMENT | DOWNLOAD |

EDI Module Water Treatment | DOWNLOAD PDF |

High Purity Water: EDI produces ultra-pure water with minimal ions, making it ideal for applications requiring exceptional purity.

Reduced Maintenance: Unlike ion exchange which requires regular chemical regeneration, EDI continuously cleans the resin beds using an electric current. This eliminates the need for handling harsh chemicals and simplifies maintenance.

Environmentally Friendly: EDI avoids the use and disposal of regeneration chemicals, minimizing environmental impact.

Consistent Performance: The continuous regeneration process ensures consistent water quality, unlike ion exchange which experiences performance decline as the resins become exhausted.

Cost-Effective: While the initial investment might be higher, EDI offers lower operating costs due to reduced maintenance and chemical use.

Process Principles

Enhanced transfer regime (high salinity)

– Remove strong ions from water

Electroregeneration regime (low salinity)

– Remove ionizable species (weak acids or weak bases) from water

Coagulation/Flocculation: Chemicals are added to water to create tiny, sticky particles called "floc." These particles attract dirt, bacteria, and other impurities, forming larger particles.

Sedimentation: The water is then allowed to sit so that the larger particles (floc) settle to the bottom of the container due to their weight, forming sediment.

Filtration: The clarified water moves through filters made of sand, gravel, and charcoal to remove remaining smaller particles and impurities.

Disinfection: This step kills any remaining bacteria, viruses, and parasites that may be in the water. Common disinfection methods include chlorination, ultraviolet (UV) light treatment, or ozone treatment.

Storage and Distribution: After treatment, the water is stored in tanks or reservoirs.

The most cost-effective way to upgrade RO purified water system (PW) to high purified water system (HPW).

Effective minimum flow interlocking and current overload protection device.

Excellent water quality performance under different working conditions.

Front and rear UV devices (optional), thermal disinfection module (optional).

PLC+HMI full-automatic control mode.

Fully comply with GMP, USP and cGMP requirements.

Phone:

E-mail:

Address:

Room 1904, Building 10, No. 218, Jiqingmen Street, Jianye District, Nanjing, Jiangsu, China