Reverse osmosis device (RO device for short) is a key equipment in the salt removal system. The device uses membrane separation technology to remove most ions and SiO2 in the water, greatly reducing TDS and reducing the operating load of subsequent salt removal equipment. RO is to pass part of the raw water through the film in the direction perpendicular to the film, the salt and colloidal substances in the water will concentrate on the surface of the film, and the remaining part of the raw water will take away the concentrated substances in the direction parallel to the film, and clean itself during the operation. The greater the water flux of the membrane element and the higher the recovery rate, the higher the degree of concentration of the membrane surface. Due to the concentration, the solubility of the material on the membrane surface is different from the concentration of the material in the main flow, resulting in the phenomenon of concentration polarization. Concentration polarization will make the salt concentration on the surface of the film is high, increase the osmotic pressure of the film, cause the salt permeability to increase, and in order to improve the water pressure and need to consume more energy, at this time should be used to restore the method of cleaning.

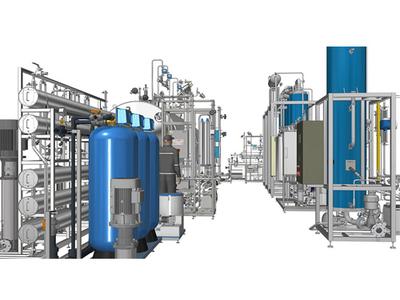

The reverse osmosis plant is composed of composite membrane element, FRP pressure vessel, carbon steel slide frame and instrument control cabinet. Instrument control cabinet is equipped with conductance, flow, pressure and other instruments, which is convenient for users to detect at any time and realize automatic operation of the device.

The installation of reverse osmosis devices shall be performed in accordance with the following conditions:

After the device is delivered to the site, it should be placed indoors with the ambient temperature not lower than 5℃ and not higher than 38℃. When the temperature is higher than 35 ° C, ventilation measures should be strengthened.

The device shall be installed within one month after its arrival, and shall be immediately put into water trial operation.

After the device is delivered to the site, it should be placed indoors with the ambient temperature not lower than 5℃ and not higher than 38℃. When the temperature is higher than 35 °C, ventilation measures should be strengthened.

The device shall be installed within one month after its arrival, and shall be immediately put into water trial operation.

Device before make water test, any valve shall be open, so as not to protect solution out of the country, the damage of components.

After the device is in place, the support point of the device should be adjusted so that the component is in a basic level position and reliable contact with the foundation.

The pipeline and valve connected with the water supply pump should be degreased before connection, and the over-flow part of the water supply pump should also be degreased.

The maximum output height of the water production output pipe of the device should be less than 8 meters.

Note: Points 2 and 3 are only for devices with membrane elements installed in the RO device.

The inlet water of the device is analyzed and tested, and the results show that it meets the inlet water requirements, and the water commissioning of the device can be carried out.

Adjust the pressure control of the water supply pump and the water quality automatic monitoring system.

Check whether all pipes of the device are properly connected, whether the pressure gauge is complete, and whether the low-pressure pipe connection is tight or short.

Open the discharge valve before the pump, start the pretreatment equipment, and adjust the water supply is greater than the device water intake.

Open all pressure gauge switches, water inlet valve, concentrated discharge valve, and water production discharge valve.