Water is the most widely used raw material in pharmaceutical manufacturing. Whether it's for cleaning, formulation, or as a direct ingredient in non-parenteral drug products, water quality directly impacts product safety and compliance. Pharmaceutical purified water systems must deliver consistent purity, efficiency, and regulatory compliance.

This article provides an in-depth guide to pharmaceutical purified water systems, their technologies, and the advantages of partnering with Biocell Environmental Technology, a trusted global provider of turnkey water treatment solutions.

Pharmaceutical purified water systems are designed to produce water that complies with the specifications of international pharmacopeias such as the USP (United States Pharmacopeia), Ph. Eur. (European Pharmacopoeia), and JP (Japanese Pharmacopeia). Purified Water (PW) is typically used for:

Non-injectable drug formulations

Cleaning of manufacturing equipment

Rinsing of primary packaging materials

Laboratory applications

To meet these demands, purified water must be free from:

Suspended particles

Organic and inorganic contaminants

Microbial contaminants

Endotoxins (within allowable limits)

At Biocell, we design purified water systems that meet and exceed pharmacopeial requirements, integrating robust engineering, smart automation, and regulatory validation support.

The role of purified water goes beyond simple utility—it's a critical quality component in manufacturing. Here's why it matters:

Purified water must comply with the pharmacopeia limits for:

Conductivity (≤ 1.3 μS/cm at 25°C, USP)

Total Organic Carbon (TOC ≤ 500 ppb)

Microbial count (≤ 100 CFU/mL)

Contaminated water can compromise drug safety, stability, and efficacy, leading to costly recalls and regulatory penalties.

High-purity water protects process equipment from corrosion, fouling, and scale formation, extending equipment life and reducing maintenance costs.

Reliable purified water systems ensure uninterrupted production with reduced downtime and cleaning cycles.

Biocell’s solutions are tailored for 24/7 operation in GMP environments, ensuring consistent water quality that safeguards both processes and patients.

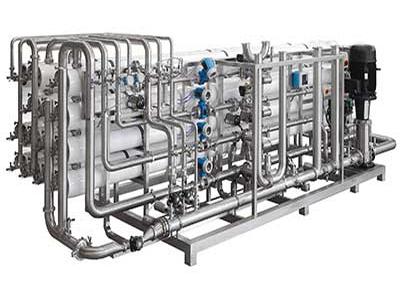

Pharmaceutical purified water systems can vary depending on process needs, capacity, and regulatory requirements. Biocell offers a range of solutions, including:

Removes up to 99% of dissolved salts and organics

Commonly used as the first purification stage

Polishes RO permeate to achieve ultra-low conductivity

Eliminates the need for chemical regeneration

Removes endotoxins and high molecular weight organics

Used in systems where microbial control is critical

Includes softeners, activated carbon, and media filters

Protects downstream purification components

| Application | Water Type | System Components |

|---|---|---|

| Oral formulations | PW | RO + EDI |

| Equipment rinsing | PW | RO + UV |

| Laboratory prep | PW | RO + UF |

| Final rinse in CIP/SIP | PW | RO + UV + Storage Loop |

To ensure consistent purity, Biocell incorporates advanced technologies across all stages of purification:

Real-time monitoring of key parameters: TOC, conductivity, temperature, and pressure

21 CFR Part 11-compliant data logging and audit trails

Thermal sanitization (>80°C) or chemical sanitization options

Automatic sanitization cycles minimize biofilm risk

Maintains high flow velocity to prevent microbial stagnation

Sloped piping design for full drainability

Cloud dashboards for remote access

Instant alerts for deviation detection and troubleshooting

Heat recovery and low-energy RO modules

Variable frequency drives (VFDs) on pumps for demand-based control

These technologies enable predictive maintenance, optimized energy use, and minimal operational risks.

A well-designed purified water system should be efficient, compliant, and future-ready. Here are key design principles Biocell follows:

System capacity must reflect current and projected demand. Oversized systems waste energy and increase microbial risk; undersized systems hinder production.

Biocell uses high-grade 316L stainless steel, with electropolished and passivated surfaces, compliant with ASME BPE standards.

Continuous recirculation

Dead-leg-free design (<1.5x pipe diameter)

Sloped piping for complete drainage

Biocell delivers full validation support including:

URS, FS, DQ, IQ, OQ, and PQ protocols

FAT/SAT testing

Calibration and commissioning

All systems are designed to meet:

cGMP

USP <1231>, <643>, <645>

Ph. Eur. 0169

FDA and EMA guidelines

Biocell Environmental Technology is a global leader in pharmaceutical water system solutions. Our purified water systems are used by top pharmaceutical and biotech companies for their reliability, compliance, and efficiency.

Over 20 years of experience in water treatment for life sciences

Customized turnkey systems including design, fabrication, automation, and validation

Energy-efficient and sustainable technologies

Global regulatory expertise (FDA, EMA, WHO, CFDA)

RO + EDI Purified Water Systems

Ultrafiltration Units for Endotoxin Control

Thermal and Chemical Sanitization Loops

Distribution Skids with Real-Time Monitoring

Pre-treatment Packages for Feedwater Quality

From conceptual design to commissioning and after-sales support, Biocell is your long-term partner in pharmaceutical water purification.

Pharmaceutical purified water systems are the backbone of non-sterile drug manufacturing. With growing regulatory pressure and the demand for consistent product quality, investing in a well-engineered, digital-ready, and validated water system is non-negotiable. Biocell Environmental Technology offers proven solutions that combine engineering excellence, automation, and full lifecycle support.