Distilled water is purified water fully preheated through multi-stage evaporation and condensation to eliminate non-condensable gases and impurities, thus obtaining high-purity water for injection.

Compared with the tower distillation machine, the multi-effect distillation machine has a higher temperature, which is conducive to the inhibition of microbial reproduction of water for injection, the equipment covers an area of small, relatively simple maintenance, and has become the main production equipment for water for injection in the pharmaceutical industry.

Multi-effect water distillation machine usually consists of multiple evaporation heat exchangers, separation devices, preheaters, two condensers, valves, instruments and control parts.

Since in this segmented evaporation and condensation process, only the first effect evaporator needs external heat source for heating, the pure steam produced by the last effect and the condensation of the water for injection produced by each effect is cooled by external cooling medium, so it is very effective in energy saving.

In the multi-effect water distiller, the purified steam produced by the multi-effect evaporator is pure steam used to heat the raw water, and the pure steam is condensed into the injection water through phase change after heating and evaporating the raw water.

The number of effects of conventional multi-effect water distillation machine is 3-8 effects, each effect includes an evaporator, a separation device and a preheater, the more effects, the better the energy-saving effect.

In the case of a certain amount of water for injection, in order to reduce the consumption of steam and cooling water, it is necessary to increase the number of effects, but this will increase investment costs, for this reason, to choose the right number of effects, which requires the pharmaceutical manufacturer to determine the buyer and manufacturer together.

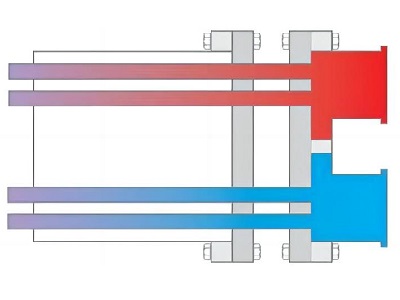

To prevent cross-contamination of the system, the first evaporator, all the pre-heater and condenser of the multi-effect distilled water machine are designed with double-ended plate and tube. The inner tube plate and outer tube plate adopt the most advanced double-expansion technology in the world. Double-expansion technology belongs to the physical processing method, which connects the column tube and the tube plate through the expander to fix, and requires high processing precision, and can be used in clean equipment or systems with working pressure not exceeding 10 bar.

Because the welding process is avoided, the double-expansion method can well eliminate the chemical crystal change corrosion caused by the heat exchanger welding, so the risk of heat exchanger leakage is extremely low, greatly extending the service life of the multi-effect distilled water machine.