In the pharmaceutical industry, ensuring purity is of utmost importance. From the manufacturing process to the final product, every step must adhere to strict quality standards. One crucial aspect of maintaining pharmaceutical purity is the use of pure steam generators. These ingenious machines play a vital role in producing steam of the highest quality, free from impurities that could compromise the integrity of pharmaceutical products. This article aims to shed light on the working principle of pure steam generators and their significance in achieving pharmaceutical purity.

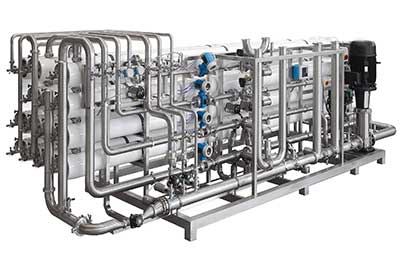

Pure steam generators are specialized equipment designed to produce pure steam for the pharmaceutical industry. Unlike industrial steam generators, which are commonly used for applications such as heating and power generation, pure steam generators are specifically designed to meet the stringent requirements of pharmaceutical production. They ensure the steam produced is free from contaminants and suitable for use in critical processes like sterilization and sanitization.

The working principle of pure steam generators revolves around the concept of multiple stage evaporation. The process begins with the feedwater being heated in a shell-and-tube heat exchanger. This initial heating stage removes most of the non-condensable gases, dissolved gases, and volatile impurities present in the water. The partially purified feedwater then enters the next stage, which is typically a vertical separator.

In the vertical separator, the feedwater is exposed to a series of steam-water separators, creating a cascading effect. This enables the removal of any remaining impurities, such as entrained particles and droplets, from the steam. The purified steam rising up through the vertical separator is then collected and condensed, ensuring its purity. The condensed pure steam is subsequently stored in a storage tank for later use in pharmaceutical processes.

Pure steam generators play a critical role in achieving pharmaceutical purity by providing a reliable source of steam free from impurities. The high purity levels achieved by these generators eliminate the risk of contamination, ensuring that pharmaceutical products remain safe and effective. Pure steam is commonly used in various pharmaceutical processes, such as sterilization, cleaning, and air humidification, where any impurities could compromise the quality of the final product.

Given the critical role of pure steam generators in maintaining pharmaceutical purity, they must comply with strict regulatory standards. These standards emphasize the need for validation and regular monitoring of the equipment to ensure its continuous performance in generating pure steam. The validation process typically involves verifying the overall performance, integrity, and effectiveness of the generator in eliminating impurities. Periodic testing, calibration, and maintenance are essential to maintain compliance with regulatory requirements and ensure the consistent production of pure steam.

The working principle of pure steam generators involves a multi-stage evaporation process to produce steam free from contaminants. Their significance in achieving pharmaceutical purity cannot be overstated, as they provide a reliable source of steam for critical pharmaceutical processes without compromising the quality of the final product. By complying with regulatory standards and undergoing validation, pure steam generators ensure the integrity and safety of pharmaceutical production, ultimately contributing to the well-being of patients worldwide.