If you’re in the pharmaceutical world, you’ve probably heard of a WFI heat exchanger. But what exactly does it do, and why is it such a big deal in producing Water for Injection (WFI)? Let’s break it down in a way that’s easy to grasp, whether you’re a curious newbie or a seasoned engineer. Plus, we’ll explore why these systems are critical, how they fit into pharmaceutical processes, and what makes them tick. Buckle up for a journey into the heart of WFI production!

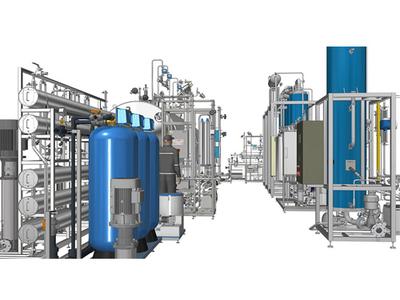

A WFI heat exchanger is a specialized piece of equipment designed to transfer heat between two fluids—typically water or steam—without mixing them. In pharmaceutical manufacturing, it’s used to heat or cool water to produce WFI, which is ultra-pure water meeting strict regulatory standards for injectable drugs. Think of it as the unsung hero ensuring your medicines are safe and sterile.

Water for Injection is the gold standard for purity in pharma. It’s used in everything from drug formulation to equipment cleaning. A WFI heat exchanger ensures this water reaches the right temperature for processes like sterilization or distillation, all while maintaining its purity. No contamination, no compromises.

The global WFI market is growing fast, driven by rising demand for injectable drugs. A reliable WFI heat exchanger isn’t just equipment—it’s a cornerstone of compliance and quality for pharma companies.

At its core, a WFI heat exchanger operates on a simple principle: heat transfer without direct contact. Here’s a step-by-step look at how it gets the job done:

Two Fluids, No Mixing: The exchanger has two separate flow paths—one for the WFI (or water being purified) and another for a heating/cooling medium (like steam or chilled water). These fluids never mix, thanks to a physical barrier like tubes or plates.

Heat Transfer Magic: The hot fluid (e.g., steam) transfers its heat through the barrier to the cooler WFI. This can heat the water to precise temperatures for distillation or sterilization.

Maintaining Purity: The design—often a double-tube sheet or plate system—prevents leaks and contamination, critical for meeting Good Manufacturing Practices (GMP).

Temperature Control: Advanced WFI heat exchangers use sensors and automation to maintain exact temperatures, ensuring consistency and compliance.

Here’s a quick visual to make it clearer:

Component | Role |

|---|---|

Tubes/Plates | Separate fluids and facilitate heat transfer |

Shell | Houses the tubes and directs fluid flow |

Inlet/Outlet Ports | Allow fluids to enter and exit without mixing |

Seals/Gaskets | Prevent leaks to maintain WFI purity |

Not all WFI heat exchangers are created equal. Here’s a rundown of the main types you’ll encounter:

Type | Description | Best For |

|---|---|---|

Shell-and-Tube | Tubes inside a shell transfer heat; robust and versatile | High-pressure, high-volume WFI production |

Plate Heat Exchanger | Stacked plates for compact, efficient heat transfer | Space-constrained facilities |

Double-Tube Sheet | Extra barrier to prevent cross-contamination | Ultra-high purity requirements |

Each type has its strengths, but double-tube sheet designs are especially popular in pharma for their fail-safe contamination prevention.

Choosing the right WFI heat exchanger depends on your facility’s throughput, space, and regulatory needs. A misstep here could mean costly downtime or compliance issues.

WFI heat exchangers aren’t just about heating or cooling—they’re about precision and reliability. Here’s why they’re critical:

Regulatory Compliance: WFI must meet USP, EP, or JP standards. A well-designed heat exchanger ensures consistent quality.

Energy Efficiency: Modern designs optimize heat transfer, cutting energy costs—a win for both your budget and the planet.

Scalability: Whether you’re a small biotech or a global pharma giant, WFI heat exchangers can be tailored to your production scale.

No system is perfect. WFI heat exchangers face a few hurdles:

Fouling: Mineral deposits or biofilm can reduce efficiency. Solution: Regular cleaning with validated CIP (Clean-in-Place) protocols.

Material Corrosion: Harsh conditions can degrade components. Solution: Use high-grade stainless steel (e.g., 316L) or other corrosion-resistant materials.

Temperature Control: Precise control is non-negotiable. Solution: Invest in automated systems with real-time monitoring.

Maintenance isn’t just about fixing problems—it’s about preventing them. A proactive maintenance schedule can extend your WFI heat exchanger’s lifespan by years.

How do WFI heat exchangers stack up against other heat transfer systems? Unlike standard industrial heat exchangers, WFI systems prioritize purity and compliance over raw power. For example, a food-grade heat exchanger might handle higher volumes but won’t meet pharma’s stringent standards.

The WFI heat exchanger world is evolving. Look out for:

Energy-Saving Designs: New materials and configurations are boosting efficiency.

Smart Automation: IoT-enabled exchangers monitor performance in real-time, reducing human error.

Sustainability: Pharma is pushing for greener systems, and WFI heat exchangers are no exception.

At Biocell Pharma, we get that a WFI heat exchanger isn’t just equipment—it’s a lifeline for your production. Our systems are designed with GMP compliance, scalability, and ease of maintenance in mind. Whether you need a compact plate exchanger or a robust double-tube sheet system, we’ve got you covered with solutions that keep your WFI pure and your operations smooth.

Partnering with a supplier like Biocell Pharma means more than just buying equipment. It’s about getting tailored solutions and expert support to meet your specific needs.

To get the most out of your WFI heat exchanger, follow these practical tips:

Regular Inspections: Check for leaks, corrosion, or fouling monthly.

Validated Cleaning: Use CIP protocols to maintain purity without dismantling the system.

Monitor Performance: Track temperature and pressure to catch issues early.

Train Your Team: Ensure operators understand GMP requirements and exchanger specifics.

A WFI heat exchanger might not be the flashiest piece of equipment in a pharma facility, but it’s a workhorse that keeps your WFI production on track. From ensuring purity to meeting regulatory standards, it’s a critical piece of the puzzle. By understanding how it works, choosing the right type, and staying on top of maintenance, you’re setting your operation up for success.