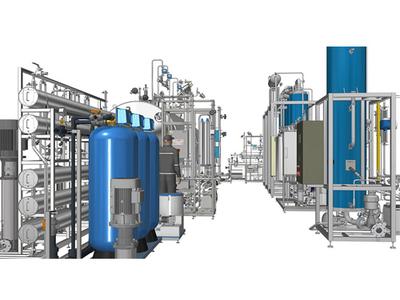

In industries with extremely high water quality requirements, such as pharmaceuticals, medical, and laboratories, WFI (Water for Injection) is a special water source that must achieve ultra-high purity. To ensure that WFI maintains a stable temperature and sterile state during use and transportation, WFI heat exchangers play a crucial role as core temperature control equipment. This article will take you through the fundamental principles, core advantages, and application scenarios, to help you understand the key value of WFI heat exchangers in injection water systems.

WFI heat exchangers are specially designed heat exchange devices for injection water systems, primarily used for heating, cooling, or thermal control of WFI. Their design must comply with the strict requirements of GMP (Good Manufacturing Practice) and FDA (U.S. Food and Drug Administration) to avoid contamination, heat source leakage, or bacterial growth.

The WFI heat exchanger usually adopts a double-tube sheet structure, fully welded with no dead angles, and are made of medical-grade stainless steel (such as 316L) to ensure good sealing and cleanliness under high-temperature and high-pressure environments.

The purity of WFI is extremely high, making it easily contaminated by microorganisms. By strictly controlling the water temperature through the heat exchanger, it avoids temperature fluctuations that cause "cold spots," effectively preventing bacterial growth and ensuring the sterile state of WFI.

Modern WFI heat exchangers often use plate or shell-and-tube designs, achieving high heat exchange efficiency, quickly completing heating or cooling, and reducing energy waste. Some systems also support heat recovery, significantly reducing operating costs.

The internal structure of the equipment has no dead angles, and the surface is highly polished, facilitating CIP (cleaning-in-place) and SIP (sterilization-in-place) operations, preventing residue or bacterial accumulation and meeting the hygiene requirements of the pharmaceutical production environment.

Water for injection heat exchangers usually use highly corrosion-resistant stainless steel, titanium alloys, or nickel-based materials, capable of withstanding prolonged exposure to high-temperature steam, with a service life far exceeding that of ordinary industrial equipment.

Advanced heat exchange systems support real-time monitoring of temperature, pressure, and flow, can connect to a central control system, achieving automatic adjustment and fault alarm, enhancing the safety and reliability of operation.

Used for the terminal cooling, storage, and pipeline insulation of WFI, ensuring that water used in injectables or infusion products is used safely under sterile conditions.

WFI, as an essential medium for disinfecting and cleaning high-precision medical instruments, needs to maintain a suitable temperature through the heat exchanger.

Used in scenarios such as biopharmaceutical research, vaccine development, etc., which are highly sensitive to water quality and temperature control.

WFI heat exchangers are not just temperature control equipment but also important barriers to ensure the safe, stable, and efficient operation of the entire injection water system. They safeguard the quality of every drop of pure water in "invisible" aspects, supporting the high standards required by the pharmaceutical and healthcare industries. As the pharmaceutical industry enforces GMP standards more strictly, the professionalism and technical content of WFI heat exchangers will continue to improve. Choosing the right WFI heat exchange system is a key step towards high-quality production for any pharmaceutical and medical institution.