In industries such as pharmaceuticals, medical, food, and biological research, which demand extremely high water quality, ordinary pure water systems often fail to meet the requirements for high-purity water. At this point, Multi effect water distiller emerges as a core equipment for producing Water for Injection (WFI) or ultrapure water. Through multi-stage evaporation and condensation processes, this equipment not only enhances water quality but also significantly improves energy efficiency, making it an indispensable piece in modern high-standard water systems.

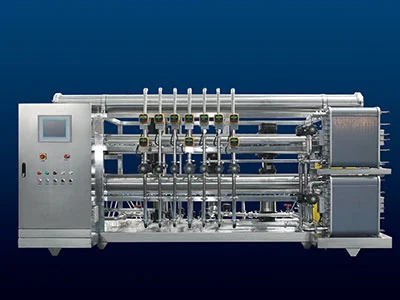

A multi effect water distiller is a water distillation device that operates using multiple evaporation units (known as "effects") in cascade. The first effect uses steam to heat the water and generate steam, which is subsequently conducted to the second effect as a heat source, and so on. Each effect can recycle the energy produced by the previous stage, thus significantly improving thermal efficiency and reducing operational costs.

This distillation method not only realizes high efficiency and energy savings but also considerably reduces microbial and impurity content, meeting international pharmacopeia standards such as GMP, USP, and EP, and is widely used in numerous high-standard industries.

In pharmaceutical processes, particularly in the manufacture of injections, vaccines, and infusion products, there are extremely high requirements for the microbial, endotoxin, and inorganic ion content of water. The multi-effect distiller can consistently output high-purity water that meets WFI standards and can operate in a sterile state for an extended period, making it a standard equipment for large pharmaceutical factories and biotechnology companies.

In hospitals, surgical centers, or sterilization supply centers, many medical devices require sterile pure water for rinsing and high-temperature sterilization. The multi-effect water distiller can provide constant temperature, high-purity distilled water, ensuring that surgical equipment and tools can be used safely in a sterile state, safeguarding patient health.

On production lines of high-end bottled water, infant formula, high-end seasonings, and other processes that are extremely particular about water sources, multi-effect distilled water is often used as addition water or as a cleaning water source for raw materials during production, ensuring that the products are free from impurities, odors, and contamination.

In the cosmetics industry, particularly for sterile skincare products (such as eye serums and skincare products for sensitive skin), the water quality requirements are nearly pharmaceutical grade. The multi-effect water distiller can provide a safe, clean core water source for this type of production, effectively preventing product deterioration due to water quality issues.

In experiments related to biology, chemical analysis, DNA research, cell culture, and others, the purity of water directly affects the reliability of experimental data. The multi-effect distiller can consistently provide high-purity water, avoiding the interference of trace impurities in the water on the experimental results, making it a crucial supporting equipment for research platforms.

High efficiency and energy-saving: The multi-effect design significantly reduces steam and cooling water consumption.

Standard compliance: The water produced can meet or exceed international pharmacopeia standards such as USP, EP, and JP.

Strong continuous operation capability: Suitable for large-scale production and round-the-clock water supply.

High degree of automation: Supports CIP/SIP, facilitating cleaning and sterilization.

Stable operation: Simple maintenance and long service life.