Ultra-pure water was initially produced by the US technology industry through distillation, deionization, reverse osmosis, or other appropriate supercritical precision techniques to produce water with a resistivity close to 18.3MΩ*CM. Ultra-pure water is free from hardness, has a sweet taste, and is often known as soft water. It can be consumed directly or boiled before consumption. Currently, it is widely used in fields such as biology, medicine, and automotive.

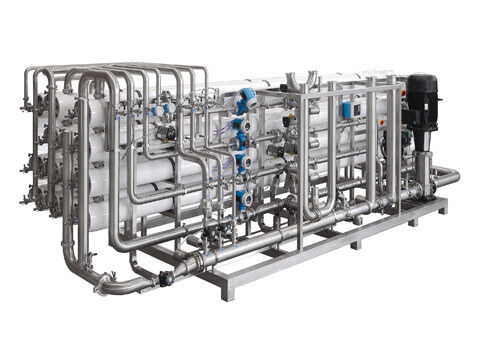

The tap water enters the pre-treatment module, where it undergoes pre-treatment to remove particulate matter, organic matter, and odors, preventing organic fouling and chlorination damage to the RO membrane.

Afterward, the water enters the reverse osmosis module through a booster pump. The reverse osmosis module uses the DP-RO two-stage reverse osmosis technology patented by Aikapu. The module has two outlets, one for the production of pure water to be temporarily stored in a pure water tank. The ions, particulates, organic molecules, and bacteria trapped by the reverse osmosis membrane are transported to the drainage outlet through a drainage pipe.

When taking water, the delivery pump is started, and the pure water is drawn from the pure water tank into the UV lamp. The UV lamp emits 185 nm and 254 nm light to reduce the organic matter and microbial content in the water. Then, the pure water is transported to the purification column module to remove the ions in the water. The ultrafiltration membrane and the water intake filter are a membrane filter used to filter out particles, bacteria, and endotoxins larger than the filter aperture. The production quality of the ultra-pure water machine is enhanced through regular water recycling.

Meanwhile, the ultrapure water systems monitor three types of water: raw water, pre-purified water, and ultra-pure water for scientific data analysis used for consumable replacement and equipment operating conditions.

The pre-treatment module, reverse osmosis module, purification column module, UV lamp, ultrafiltration membrane, and water intake filter in the system are all consumables that need periodic replacement during system maintenance.

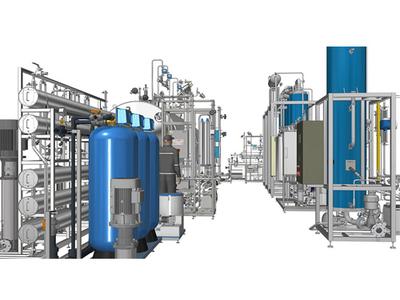

Pre-treatment system → reverse osmosis system → intermediate water tank → rough mixed bed → fine mixed bed → pure water tank → pure water pump → UV sterilizer → polishing mixed bed → precise filter → water object (≥18MΩ.CM); (Traditional process)

Pre-treatment → reverse osmosis → intermediate water tank → water pump → EDI device → purified water tank → pure water pump → UV sterilizer → polishing mixed bed → 0.2 or 0.5μm precision filter → water object (≥18MΩ.CM); (New process)

Pre-treatment → primary reverse osmosis → dosing machine (PH adjustment) → intermediate water tank → secondary reverse osmosis (positive charge reverse osmosis membrane) → pure water tank → pure water pump → EDI device → UV sterilizer → 0.2 or 0.5μm precision filter → water object (≥17MΩ.CM); (New process)

Pre-treatment → reverse osmosis → intermediate water tank → water pump → EDI device → purified water tank → pure water pump → UV sterilizer → 0.2 or 0.5μm precision filter → water object (≥15MΩ.CM); (New process)

Pre-treatment system → reverse osmosis system → intermediate water tank → pure water pump → rough mixed bed → fine mixed bed → UV sterilizer → precision filter → water object (≥15MΩ.CM); (Traditional process)

Each process has its advantages, and you can choose the appropriate process based on your situation. With the development of science, many new processes have replaced the old ones.