In pharmaceutical manufacturing, the quality and consistency of Water for Injection (WFI) play a crucial role in safeguarding product purity, patient safety, and regulatory compliance. As global GMP standards continue to tighten, selecting the right multi effect water distiller becomes an essential strategic decision for every facility. The distillation system not only determines the purity of WFI but also influences long-term operational efficiency, energy consumption, and validation requirements.

At Biocell, we regularly support pharmaceutical plants, biotech companies, and high-purity water users in evaluating and installing multi-effect distillation systems designed for reliability and compliance. This guide provides a clear, practical framework to help you select the most suitable multi effect water distiller for your production environment.

Multi-effect distillation (MED) has become the industry standard due to its ability to deliver:

Bacteria-free, endotoxin-free WFI

Low conductivity and stable TOC levels

Consistent output under variable loads

Lower steam and cooling water usage compared with single-effect systems

A multi effect water distiller operates by generating purified steam from multiple sequential “effects,” each reusing the heat from the previous stage. This cascading process significantly increases thermal efficiency while maintaining high purity.

For facilities aiming to reduce utility consumption without compromising quality, a well-designed MED system offers an ideal balance.

Your facility’s water demand profile is one of the most important sizing criteria. Consider:

Peak hourly consumption

Average daily throughput

Future capacity expansion

Batch-based vs. continuous consumption

System redundancy requirements

Undersizing leads to production delays. Oversizing increases initial cost and unnecessary energy usage. A properly sized multi effect water distiller should operate within its optimal thermal efficiency range most of the time.

Multi-effect distillers typically range from 3 to 8 effects. More effects generally provide higher energy savings but require more complex engineering and greater footprint.

| Number of Effects | Typical Benefits | Facility Type |

|---|---|---|

| 3–4 Effects | Lower initial investment, simpler maintenance | Small to mid-scale plants |

| 5–6 Effects | Balanced efficiency and cost | Standard pharmaceutical facilities |

| 7–8 Effects | Best thermal efficiency, lower steam consumption | Large-scale continuous production |

Choosing the right configuration requires evaluating your utility costs (steam, cooling water, electricity) and production schedule.

Since WFI purity must be maintained under all operating conditions, the distiller must be built with high-grade sanitary materials.

Recommended specifications include:

316L stainless steel with low sulfur content

Ra ≤ 0.5 μm internal surface roughness

Orbital welding with full drainability

Electropolishing to reduce microbial adhesion

Biocell systems follow international GMP and ASME BPE standards to ensure long-term corrosion resistance and hygienic performance.

A multi effect water distiller can only produce stable WFI when the incoming feedwater is properly conditioned. Poor feedwater increases scaling, reduces heat exchange performance, and raises WFI conductivity.

Before selecting a system, review:

RO or EDI feedwater quality

Hardness and silica levels

TOC trends

Microbial load

Conductivity at distribution temperature

A well-matched pretreatment line protects the distiller and minimizes downtime.

Energy efficiency is becoming one of the top decision-making factors. Modern systems are designed to optimize:

Steam consumption

Cooling water demand

Heat recovery capability

Electrical load of pumps and instrumentation

Biocell often conducts utility cost modeling before system selection. This helps facilities understand long-term OPEX differences among multi effect water distiller configurations.

A high-purity distillation system must offer precise and reliable control. Look for automation capabilities such as:

Real-time monitoring of key quality attributes (TOC, temperature, conductivity)

Automatic hot standby mode

Audit-friendly data logging

Alarm management and remote diagnostics

Integration with SCADA / DCS platforms

A well-designed control system not only improves WFI quality stability but also simplifies GMP documentation and validation.

Different facilities operate on different production cycles. The chosen distiller should support:

Rapid startup times

Efficient cool-down periods

Automated hot water or pure steam sanitization

Stable output under fluctuating loads

Systems engineered with smooth transitions minimize thermal stress and extend equipment lifespan.

A multi effect water distiller is a long-term investment, often expected to run for 15–20 years. Therefore, lifecycle considerations are as important as the initial cost.

Evaluate:

Ease of replacing gaskets

Cleaning access points

Spare part availability

Expected scaling tendencies

Cost of utilities over system lifetime

Biocell designs prioritize minimal downtime and user-friendly access to critical components.

Before finalizing a system, it is recommended to conduct a structured comparison. Below is a practical evaluation checklist:

| Evaluation Category | Key Questions |

|---|---|

| Purity Performance | Does it consistently meet global WFI standards? |

| Capacity | Does it meet peak and future capacity needs? |

| Energy Efficiency | How much steam and cooling water does it consume? |

| Compliance | Does it follow GMP, USP, EP, ASME BPE requirements? |

| Control System | Is automation robust and audit-ready? |

| Operation Flexibility | Does it tolerate load fluctuations? |

| Maintenance | Is long-term serviceability straightforward? |

| Lifecycle Cost | What is the total cost over 10–15 years? |

A structured evaluation reduces risks and ensures that the selected system aligns with your operational and quality goals.

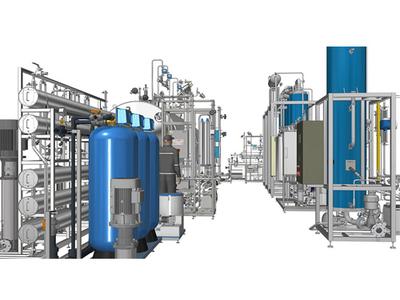

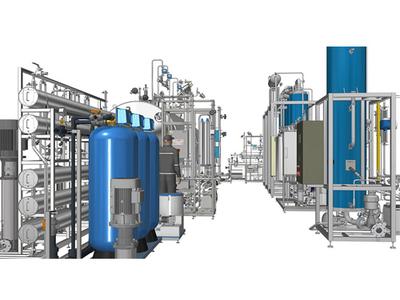

Biocell provides pharmaceutical-grade water generation and purification solutions tailored to the technical and regulatory requirements of each facility. Our multi effect water distiller systems emphasize:

High thermal efficiency through optimized multi-effect design

GMP-compliant material construction

Low-maintenance sanitary engineering

Intelligent automation with precise control

Customizable capacities for both small and large-scale applications

Our engineering team conducts detailed application assessments—covering water consumption, utility supply, layout constraints, and validation expectations—to guide clients toward the best-matched solution.

Choosing the right multi effect water distiller is essential for ensuring stable WFI production, regulatory compliance, and long-term operational efficiency. By carefully evaluating capacity needs, thermal design, materials, automation features, and lifecycle cost, facilities can make informed decisions that support both current and future production demands.

With Biocell’s experience in pharmaceutical water systems and GMP-focused engineering, we help facilities deploy reliable, efficient, and compliant WFI generation solutions designed to perform for years.

This is the first one.