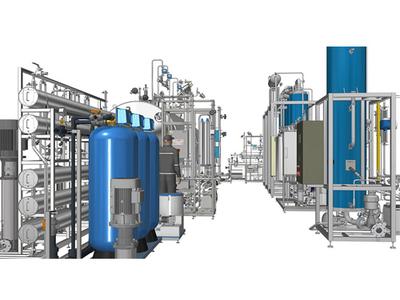

A Water for Injection (WFI) machine is a specialized system designed to produce high-purity water that meets stringent pharmaceutical standards. WFI is primarily used in the preparation of parenteral solutions, where the presence of impurities can pose significant health risks.

Biocell offers a range of WFI generation systems, including multi-effect distillers, single-effect distillers, electrically heated distillers, and cold generation systems. These systems are engineered to ensure the production of WFI that complies with global pharmacopeial standards.

Water for injection machine typically employs distillation processes to achieve the required water purity. The most common methods include:

Multi-Effect Distillation (MED): Utilizes a series of evaporators (effects) where steam from one effect is used to heat the next, enhancing energy efficiency.

Vapor Compression Distillation (VCD): Compresses and recycles vapor to generate distilled water, suitable for facilities with limited utilities.

Reverse Osmosis (RO) with Ultrafiltration: Some systems incorporate RO followed by ultrafiltration to remove contaminants, although distillation is often preferred for WFI production.

Biocell's WFI systems are designed with these technologies to ensure consistent production of high-quality water.

Producing WFI necessitates adherence to strict regulatory standards to ensure safety and efficacy:

United States Pharmacopeia (USP): Defines WFI as water purified by distillation or a purification process equivalent or superior to distillation in the removal of chemicals and microorganisms.

European Pharmacopoeia (Ph. Eur.): Allows WFI production by distillation or by reverse osmosis coupled with appropriate techniques, provided it meets quality standards.

Current Good Manufacturing Practices (cGMP): Mandates regular monitoring, validation, and maintenance of WFI systems to prevent contamination.

Biocell ensures that its WFI systems comply with these international standards, providing documentation and support for regulatory compliance.

Selecting an appropriate WFI machine involves considering several critical factors:

| Factor | Considerations |

|---|---|

| Production Capacity | Assess daily WFI requirements to choose a system with adequate output. |

| Energy Efficiency | Evaluate energy consumption; multi-effect distillers are more energy-efficient than single-effect units. |

| Space Constraints | Consider the physical footprint of the system relative to available space. |

| Maintenance Requirements | Opt for systems with user-friendly maintenance protocols and readily available spare parts. |

| Regulatory Compliance | Ensure the system meets all relevant pharmacopeial and cGMP standards. |

Biocell offers customizable WFI solutions tailored to meet specific operational needs and constraints.

WFI is indispensable in various pharmaceutical applications, including:

Parenteral Preparations: Used as a solvent in the formulation of injectable drugs.

Sterile Equipment Cleaning: Employed in cleaning and rinsing equipment to prevent microbial contamination.

Biological Product Manufacturing: Utilized in the production of vaccines and other biologics where sterility is paramount.

Analytical Testing: Serves as a solvent or diluent in quality control laboratories.

Biocell's WFI systems are designed to support these applications, ensuring consistent water quality for critical pharmaceutical processes.

Regular maintenance is vital to ensure the longevity and performance of WFI systems:

Routine Inspections: Conduct regular checks for signs of wear, corrosion, or microbial growth.

Sanitization Protocols: Implement periodic sanitization procedures to prevent biofilm formation.

Monitoring Systems: Utilize automated monitoring for parameters like conductivity, temperature, and flow rates to detect anomalies promptly.

Documentation: Maintain detailed records of maintenance activities to comply with regulatory requirements.

Biocell provides comprehensive support for the maintenance and optimization of its WFI systems, including training, documentation, and technical assistance.