In the pharmaceutical and biotech industries, Water for Injection (WFI) must meet stringent quality standards and is typically produced using thermal distillation. Two of the most commonly used distillation methods are Vapor Compression Distillation (VC) and Multi Effect Distillation (MED). Choosing the right distiller is critical for energy efficiency, operational stability, and compliance with global regulations such as USP, Ph. Eur., and cGMP.

In this article, we explore the working principles, differences, and comparative advantages of Vapor Compression Distillers and Multi Effect Distillers to help you make an informed decision for your facility.

Vapor Compression Distillation (VC) is a highly energy-efficient method for producing pharmaceutical-grade water, particularly Water for Injection (WFI). This system uses mechanical or thermal compression to recycle latent heat from the vapor phase and significantly reduce overall energy consumption.

Evaporation: Feed water is heated to produce steam in an evaporator chamber.

Compression: The generated vapor is compressed mechanically (using a compressor or blower), increasing its pressure and temperature.

Condensation: The high-temperature vapor is then used to heat incoming feed water, condensing into WFI in the process.

This closed-loop mechanism minimizes the need for external steam, making VC distillers particularly suitable for facilities with limited utilities or a focus on sustainability.

Small to medium-capacity WFI generation

Facilities prioritizing low energy usage

Remote or decentralized production units

Multi Effect Distillation (MED) is a widely accepted method for high-volume WFI production. It operates on the principle of using multiple stages or "effects" where steam generated in one chamber is reused in the next, thereby conserving energy.

First Effect: External clean steam heats the first effect, boiling the feed water to produce pure vapor.

Subsequent Effects: The vapor from the first effect becomes the heating source for the second effect, and this process repeats through multiple stages.

Condensation: Pure WFI is collected from each effect as the vapor condenses.

The number of effects typically ranges from 3 to 7, with energy efficiency increasing with more effects.

Large-scale pharmaceutical production

Centralized WFI plants

Facilities with stable steam supply

Here’s a quick side-by-side comparison of VC and multi effect distiller:

| Feature | Vapor Compression (VC) | Multi Effect Distillation (MED) |

|---|---|---|

| Energy Source | Electricity (compressor) | Plant steam |

| Utilities Required | Cooling water + electricity | Plant steam + cooling water |

| Capacity Range | 100 – 5,000 L/h | 500 – 20,000+ L/h |

| Start-up Time | Short | Longer |

| Footprint | Compact | Larger (due to multiple columns) |

| Noise Level | Higher (due to compressor) | Lower |

| Maintenance Needs | Moderate (compressor wear) | Low (static system) |

| Energy Efficiency | High (closed-loop energy use) | High (when multiple effects are used) |

VC distillers are more efficient in terms of electricity use and require minimal external steam.

MED units become more efficient with higher numbers of effects but rely on a steady supply of clean steam.

VC is more sensitive to compressor performance and feedwater quality.

MED offers robust long-term operation with fewer moving parts, making it suitable for 24/7 operation.

VC systems may require more frequent service for mechanical components like the compressor.

MED systems have simpler mechanical designs, leading to longer service intervals.

VC units heat and start up quickly, ideal for batch operations.

MED systems take longer to reach steady-state but are optimal for continuous processes.

Low Steam Requirement

– Ideal for facilities with limited steam availability or aiming to reduce operational costs.

Energy Recovery

– Compresses and reuses vapor heat, significantly cutting down on energy waste.

Compact Design

– VC systems from Biocell are space-efficient, perfect for installations with limited floor space.

Quick Start-Up

– Rapid readiness makes it suitable for intermittent or batch production.

Environmental Sustainability

– Reduced carbon footprint through minimized steam usage and energy-efficient operation.

High Output

– Capable of producing large volumes of WFI, making it the go-to for large-scale pharmaceutical manufacturing.

Excellent Microbial Control

– Multiple heating and condensation stages ensure reliable endotoxin removal.

Long-Term Operational Reliability

– Fewer moving parts reduce the risk of mechanical failure and extend service life.

Proven Technology

– Widely accepted by regulatory bodies globally (FDA, EMA, WHO).

Lower Operational Costs at Scale

– More energy-efficient than single-effect systems when scaled to 5+ effects.

Selecting between VC and MED depends on several facility-specific factors. Here are some key considerations:

| Decision Factor | Recommendation |

|---|---|

| Available Utilities | VC if steam is limited; MED if steam is stable |

| Required Capacity | MED for large volume; VC for small-medium |

| Space Constraints | VC for limited footprint |

| Operational Mode | VC for batch or intermittent use |

| Energy Efficiency Goals | VC for sustainability focus |

| Maintenance Preferences | MED for low-maintenance environments |

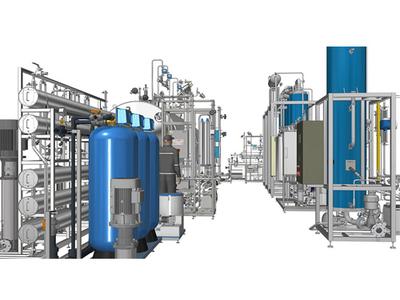

At Biocell Environmental Technology, we offer both Vapor Compression Distillers and Multi Effect Distillers tailored to meet GMP and pharmacopeial standards. Our systems are fully automated, CIP/SIP-compatible, and include complete validation support (IQ/OQ/PQ documentation).

Both Vapor Compression and Multi Effect Distillation systems have their unique strengths. Vapor Compression offers a compact, energy-saving solution for facilities with limited utilities, while Multi Effect Distillation excels in delivering high-volume, stable WFI output with minimal maintenance.

By understanding the operational, economic, and regulatory factors, pharmaceutical manufacturers can choose the system that best aligns with their production goals. With Biocell’s engineering and compliance expertise, you can ensure the right system is integrated seamlessly into your operations.

This is the first one.