In modern pharmaceuticals, bioengineering, food processing, and medical industries, water is an indispensable fundamental resource. The purified water skid, as an integrated, efficient, and intelligent water treatment solution, is becoming the preferred choice for more and more enterprises. It not only meets strict GMP regulations but also demonstrates multiple advantages in installation, operation, maintenance, etc. This article will introduce the purified water skid from multiple perspectives to help you fully understand this critical equipment.

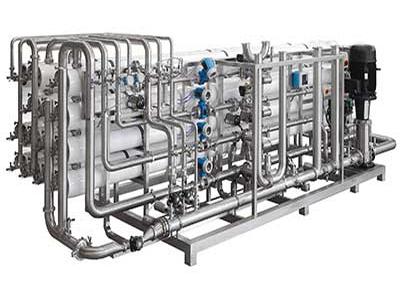

The purified water skid is a skid-mounted device that integrates multiple core process units required for purified water preparation (such as pretreatment, reverse osmosis, electro-deionization EDI, UV sterilization, precision filtration, etc.) into one. The entire system is pre-assembled and debugged in the factory and can be directly installed and used after delivery, reducing on-site construction difficulty and time.

The purified water skid usually includes the following key treatment steps:

Pretreatment (quartz sand, activated carbon): removes particulate impurities and organic matter.

Softening/Dechlorination: reduces hardness, protects the reverse osmosis membrane.

Reverse osmosis system (RO): removes more than 90% of dissolved salts and bacteria.

EDI module: further reduces conductivity to meet pharmacopeia standards.

UV sterilization + terminal microfiltration: ensures water is sterile and pyrogen-free.

CIP/SIP module: supports online cleaning and sterilization, ensuring long-term water quality stability.

The entire process is highly automated and can be controlled by PLC to achieve data monitoring, automatic flushing, alarm functions, and more.

Compared to traditional on-site assembly water treatment systems, the purified water skid has the following significant advantages:

Ready to use: Once the equipment arrives on site, it can be used as long as it is connected to the water source, power supply, and product water pipeline.

Space-saving: The modular and compact design occupies less space, suitable for tight spaces.

Reduces construction time: Avoids complicated on-site welding and assembly work.

Standardized management: Module factory manufacturing ensures consistency and compliance with validation requirements.

Easy maintenance: The equipment layout is reasonable, and all components are easy to replace and maintain.

Pharmaceutical companies: used for oral medications, topical preparations, and CIP cleaning water.

Cosmetics industry: used for producing facial cleansers, lotions, and preservative-free natural cosmetics.

Medical device cleaning: such as cleaning surgical instruments and rinsing before packaging.

Electronics manufacturing: provides ultra-low conductivity pure water for semiconductor cleaning processes.

Research laboratories: quick setup and standardized deployment of experimental pure water systems.

The purified water skid is not only an innovation in equipment integration but also represents the trend of water treatment systems towards intelligence, modularization, and standardization. It simplifies the design process, shortens the construction cycle, and ensures water quality safety and system compliance. Whether you are a pharmaceutical engineer, a laboratory manager, or a medical equipment procurement officer, understanding this advanced purified water solution in-depth will bring higher efficiency and lower risks to your project.