In modern pharmaceutical manufacturing, the reliability and efficiency of a WFI heat exchanger have a direct impact on product quality, operational cost, and long-term system stability. As regulatory expectations continue to tighten, facilities must ensure that Water for Injection (WFI) is consistently delivered at the right temperature, free from microbial contamination, and circulated under validated conditions. Achieving this level of performance does not depend solely on the purification equipment—it also relies heavily on how well the heat exchanger is designed, integrated, and controlled within the WFI distribution loop.

For companies pursuing more robust, energy-efficient, and GMP-compliant systems, choosing the right WFI heat exchanger design is no longer a secondary decision. It is a strategic investment in overall process efficiency.

In a pharmaceutical water system, the heat exchanger plays two essential roles:

Maintaining system temperature to prevent microbial growth.

Enabling smooth thermal transitions during sanitization, cooling, and distribution.

An improperly designed WFI heat exchanger can lead to prolonged heating times, temperature fluctuations, high energy consumption, and even compliance issues. On the other hand, an optimized design ensures stable performance with lower utility demand, reduced downtime, and consistent system flow.

At Biocell, we observe that many system inefficiencies originate from sizing mismatches, poor control strategies, or non-sanitary construction—issues that the right design can entirely prevent.

A WFI heat exchanger must be sized according to the actual consumption profile of the facility—not just theoretical peak loads. Oversized units waste energy, while undersized ones struggle to maintain temperature under variable flow.

A balanced sizing approach typically considers:

Distribution loop volume

Return temperature

Required point-of-use temperature

Recirculation velocity

Sanitization frequency

When the sizing aligns with real demand, the heat exchanger can operate near its optimal thermal transfer range, reducing unnecessary energy consumption.

The material must support sanitary operation and withstand thermal cycling. For pharmaceutical WFI systems, 316L stainless steel with a low surface roughness (≤ 0.5 μm Ra) remains the standard.

Key material considerations include:

Electropolishing to minimize biofilm formation

High corrosion resistance to avoid system contamination

Orbital welding compatibility for seamless integration

The right material ensures long-term durability and reduces the frequency of maintenance interventions.

Even a well-sized WFI heat exchanger becomes inefficient if the piping layout around it introduces stagnation. Dead legs allow microbial growth and reduce temperature stability across the loop.

An optimized design includes:

Fully drained piping

Short, sanitary connections

Sloped lines for full drainage

Continuous recirculation with no stagnant pockets

These measures improve thermal uniformity while reducing sanitization duration.

Different facilities require different thermal strategies depending on their utilities and sterilization practices. Common heating options include:

Steam heating: Fast response, ideal for high-purity applications

Electrical heating: Precise control, suitable for smaller loops

Hot water systems: Energy-efficient for continuous recirculation

A well-chosen heating approach provides stable temperatures while minimizing operating costs.

The two most common WFI heat exchanger types each offer advantages:

| Heat Exchanger Type | Advantages | Best Use Case |

|---|---|---|

| Plate Heat Exchanger | High heat transfer efficiency, compact design, fast thermal response | Facilities with limited space or dynamic thermal loads |

| Shell-and-Tube Heat Exchanger | Durable, easy to maintain, withstands high pressure | Large-scale WFI loops or systems prioritizing reliability |

Choosing the right type ensures a balance of performance, footprint, and cost.

Modern control systems, when paired with a well-designed WFI heat exchanger, can significantly improve efficiency. Key features include:

PID temperature control

Real-time monitoring

Flow-balanced recirculation

Automatic adjustment during point-of-use demand spikes

Such intelligence prevents overheating, reduces energy waste, and safeguards product integrity.

WFI systems typically rely on thermal sanitization to maintain microbial control. A properly designed WFI heat exchanger improves sanitization in two ways:

Faster heating and cooling cycles, reducing downtime.

Uniform temperature distribution, ensuring complete system sterilization.

This not only shortens maintenance windows but also minimizes energy consumption and ensures consistency in GMP environments.

A high-performance WFI distribution system requires more than an effective heat exchanger. It must be integrated holistically into the loop design.

Key integration elements include:

Recirculation flow rates of 1.5–2.0 m/s

Hygienic diaphragm valves

Continuous loop circulation at controlled temperatures

Accurate pressure balancing

Real-time system validation tools

When combined, these elements create a stable, efficient, and compliant distribution system.

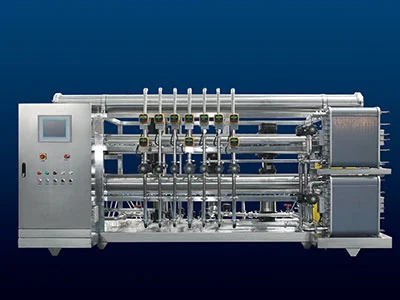

Biocell provides pharmaceutical-grade water treatment and thermal process solutions designed around global GMP standards. Our engineering team focuses on:

Energy-efficient WFI heat exchanger configurations

Hygienic system integration

Validated temperature and flow control

Long-term reliability with low maintenance needs

Through optimized design, Biocell helps manufacturers achieve stable performance, reduced operational cost, and improved system longevity.

Improving system efficiency in pharmaceutical water systems starts with selecting and designing the right WFI heat exchanger. From proper sizing and sanitary construction to energy-efficient heating strategies and intelligent control, each decision contributes to long-term stability and GMP compliance. When integrated properly, the heat exchanger becomes the foundation of a cost-effective, high-performance WFI distribution loop.

With the expertise and engineering capability to deliver tailored solutions, Biocell helps pharmaceutical manufacturers build systems that not only meet regulatory expectations but also operate with maximum efficiency and reliability.

This is the first one.