If you’re in the pharmaceutical industry, you’ve likely heard of a pure steam generator. It’s one of those behind-the-scenes workhorses that keeps your processes sterile and compliant. But how does it actually work? And why is it such a big deal for making sure medicines are safe? Let’s dive into the nuts and bolts of pure steam generators, explore their role in pharma, and unpack what makes them tick. Whether you’re new to the field or a seasoned pro, this guide’s got you covered!

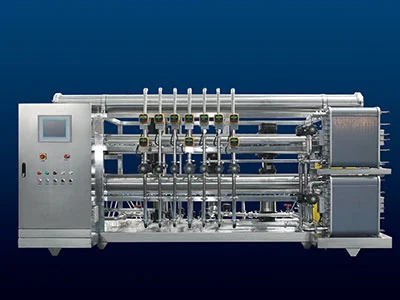

A pure steam generator is a specialized system that produces pure steam—steam that’s free of contaminants and meets strict pharmaceutical standards like USP, EP, or JP. Unlike regular industrial steam, pure steam is used for critical applications like sterilizing equipment, cleaning-in-place (CIP), or sterilizing-in-place (SIP). Think of it as the cleanest, most reliable steam you can get for making sure your production line stays pristine.

In pharma, contamination is the enemy. Pure steam ensures that equipment, vials, and other surfaces are sterilized without introducing impurities. It’s a must-have for producing injectable drugs, biologics, or any product where sterility is non-negotiable.

The demand for pure steam generators is skyrocketing as biologics and personalized medicines grow. A reliable system isn’t just equipment—it’s your ticket to regulatory compliance and patient safety.

At its heart, a pure steam generator takes purified water and turns it into high-purity steam through a carefully controlled process. Here’s how it goes down:

Feedwater Preparation: The process starts with purified water (often pre-treated to meet WFI standards). This water is fed into the generator’s evaporator.

Heating and Evaporation: The water is heated—either by electric elements or external steam—until it turns into steam. This happens in a controlled environment to prevent contamination.

Vapor-Liquid Separation: The steam passes through a separator to remove any water droplets or impurities, ensuring only pure vapor moves forward.

Delivery to Process: The clean steam is then piped to where it’s needed, like autoclaves or SIP systems, at precise temperatures and pressures.

Here’s a quick breakdown of the key components:

Component | Role |

|---|---|

Evaporator | Heats water to produce steam |

Separator | Removes water droplets and impurities |

Feedwater System | Supplies purified water to the generator |

Control System | Monitors temperature, pressure, and purity |

The separator is the unsung hero of a pure steam generator. It’s what ensures your steam is free of contaminants, making it safe for critical pharma applications.

Not all pure steam generators are the same. Here’s a look at the main types you’ll find:

Type | Description | Best For |

|---|---|---|

Electric Pure Steam Generator | Uses electric heating elements | Smaller facilities or low-volume needs |

Steam-Heated Generator | Uses external steam to heat water | High-throughput production |

Multi-Effect Generator | Multiple stages for energy efficiency | Large-scale, eco-conscious operations |

Each type has its perks, but your choice depends on your facility’s size, budget, and production demands.

Multi-effect pure steam generators are gaining traction for their energy savings—perfect for companies looking to cut costs without compromising quality.

Pure steam generators are more than just steam machines—they’re vital for:

Sterility: Pure steam ensures equipment and products are free of microbes and endotoxins.

Regulatory Compliance: Meeting USP, EP, or JP standards is a breeze with a well-designed system.

Versatility: From autoclaves to SIP and CIP systems, pure steam is a multi-tasker in pharma.

Like any system, pure steam generators have their quirks. Here’s how to handle them:

Scaling: Mineral buildup can reduce efficiency. Solution: Use high-quality feedwater and regular descaling protocols.

Energy Costs: Heating water to steam isn’t cheap. Solution: Opt for multi-effect or energy-efficient designs.

Maintenance Downtime: Regular upkeep can disrupt production. Solution: Schedule preventive maintenance and use automated monitoring.

Investing in a pure steam generator with real-time diagnostics can save you headaches. It’s like having a built-in mechanic that spots issues before they become problems.

Unlike plant steam (used in industrial settings), pure steam is produced under strict conditions to ensure no contaminants sneak in. Plant steam might be fine for heating a factory, but it’s a no-go for pharma due to potential impurities.

The pure steam generator world is evolving fast:

Energy Efficiency: New designs recycle heat to cut energy use.

Automation: Smart controls monitor steam quality in real-time.

Sustainability: Eco-friendly systems are becoming a priority as pharma goes green.

At Biocell Pharma, we know pure steam generators inside and out. Our systems are built for GMP compliance, efficiency, and reliability, whether you need a compact electric model or a high-capacity multi-effect system. We’re here to help you find the perfect fit for your facility.

Choosing a supplier like Biocell Pharma means getting more than just equipment. Our team offers tailored solutions and support to keep your operations running smoothly.

Keep your pure steam generator in top shape with these tips:

Regular Descaling: Prevent buildup with validated cleaning protocols.

Monitor Feedwater Quality: Poor water quality can harm performance.

Check Sensors: Ensure temperature and pressure controls are accurate.

Train Staff: Make sure your team knows GMP and system specifics.

A pure steam generator might not steal the spotlight, but it’s a critical player in pharmaceutical manufacturing. By producing contaminant-free steam, it ensures your products are safe and your processes are compliant. With the right system, maintenance plan, and partner like Biocell Pharma, you can keep your operation running like a well-oiled machine.

Ready to explore pure steam generators for your facility? Biocell Pharma offers cutting-edge solutions designed for performance and compliance. Reach out today, and let’s find the perfect system for you!

This is the first one.